Printing Unit

In 2005, the manufacturing division was relocated to the current Konosu-Kawasato Industrial Park (Konosu, Saitama) and started as a production plant. It is 100% owned by Taketomo.

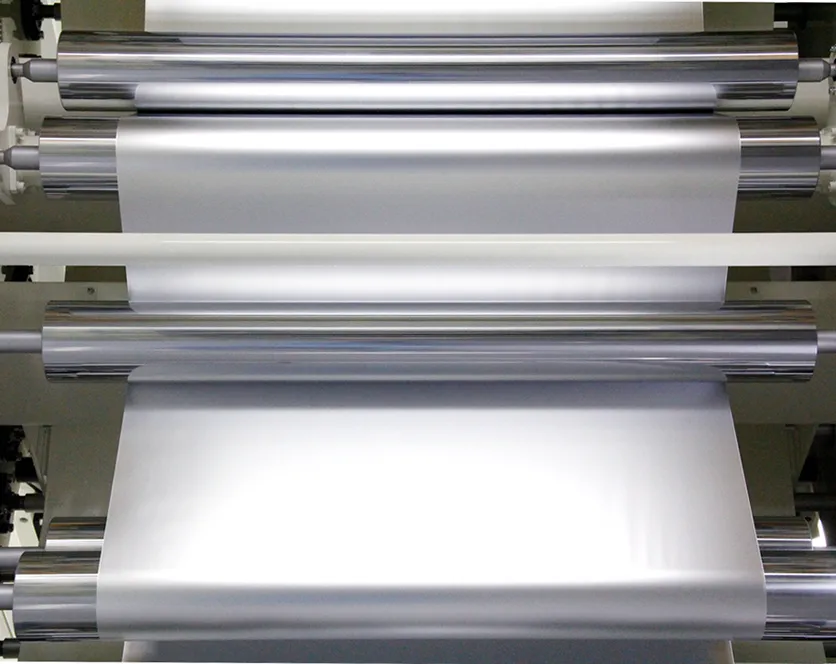

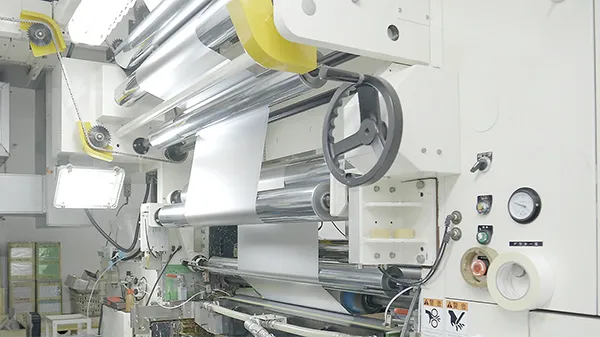

We have installed high-performance film printing machine, the latest PTP aluminium printing machine, and high-temperature drying three-head printing machine. This enables us to meet the demands of a wide range of industries, including pharmaceutical packaging, electronic devices and food packaging.

As we produce printed products that come into direct contact with the contents, the adhesion of dust, insects and body hair to the product is directly linked to safety issues. In other words, the inflow of dust into the printing room can cause various problems, such as reduced print quality. In our gravure printing process, we practice thorough cleanliness management to prevent such problems, and achieve high-quality film printing that our customers can use with peace of mind.

Printing Unit

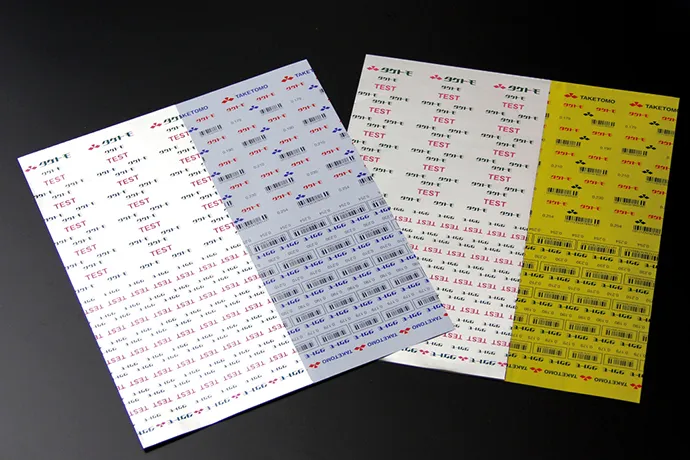

Pharmaceutical packaging requires advanced printing and processing technologies. We have introduced custom-made gravure printing machine that enables high-speed double-sided printing, while precisely aligning the front and back printing positions on PTP aluminum foil. Additionally, the machine is equipped with a high-temperature curing dryer and an online defect detection system using a CCD camera, ensuring high-quality printing.

Dual-Side Printing

Aluminium Printing Unit

Based on years of accumulated expertise, we have introduced a versatile machine that integrates printing, coating, and dry lamination. The first feeder accommodates not only plastic films but also PTP aluminum foil. Multiple coating units are installed, enabling same-side and double-sided printing with inline coating (supporting up to three-color registration). During processing, an inline inspection system ensures full-quality control, while a high-temperature drying system is utilized for optimal performance. With a wide selection of coating materials and adhesives, our capabilities extend beyond food and pharmaceutical lidding materials to include insulation for buildings, battery components, and more. We flexibly respond to a diverse range of customer needs across various industries.

Printing/Coating/Dry lamination Unit

Aluminium Printing Unit

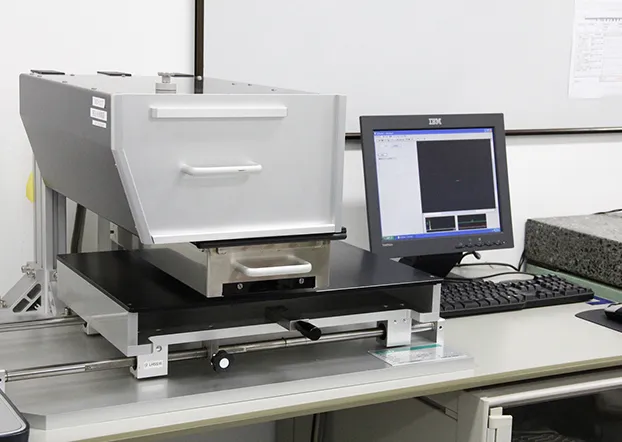

Pharmaceuticals, chemicals, and electronic devices all require delicate quality control and assured safety. Therefore, we implement strict quality management and thorough product inspections throughout all processes. During printing, an online defect detection system monitors printing defects and foreign substances, while an offline defect detection system further ensures print quality. Additionally, various measuring instruments are used to conduct inspections, ensuring that we maintain the quality standards required by our customers.

Camera based barcode verifier

IR inspection system

We have installed insect-proof shutters and air showers. Furthermore, we designate specialized dust-free garments for each clean level to ensure proper working conditions. By controlling and managing airflow through room pressure adjustments, we establish clean levels for each process, enabling high-level cleanroom printing within the industry. For insect control, we entrust specialized external contractors with thorough pest management, maintaining a consistently high level of protection.

Insect proof aisle

Air shower