Company

Greeting

"Challenging New Business Fields by Leveraging Our Accumulated Specialized Technologies and Expertise"

One of Taketomo's greatest strengths lies in our proprietary technologies in specialized fields. For instance, when it comes to PTP aluminum foil, we confidently claim to be a team of experts with unparalleled knowledge and expertise.

Over the past half-century since our founding, we have accumulated a wealth of specialized technologies and know-how. Looking toward the future, we see new possibilities to expand these capabilities into various fields. Our entry into the IC tag business marks the first step in this journey. We believe our technologies can be applied across many industries, including food, electronics, and industrial materials.

Additionally, through our commitment to eco-friendly products, we strive to develop and innovate unique technologies that focus on reducing environmental impact for our customers, society, and the planet. At the same time, we are dedicated to enhancing the reliability of our products to the highest standards.

Guided by our philosophy, "Profit is momentary, but Trust lasts forever," we aim to become a niche leader, fulfill our corporate social mission, and deliver products that contribute to people's happiness. We sincerely appreciate your continued support and patronage.

Hiroaki Ito

Quality

Striving for the Highest Quality to Earn the Words, "I'm Glad We Chose Taketomo"

Air Shower Room

Gravure Inspection Machine

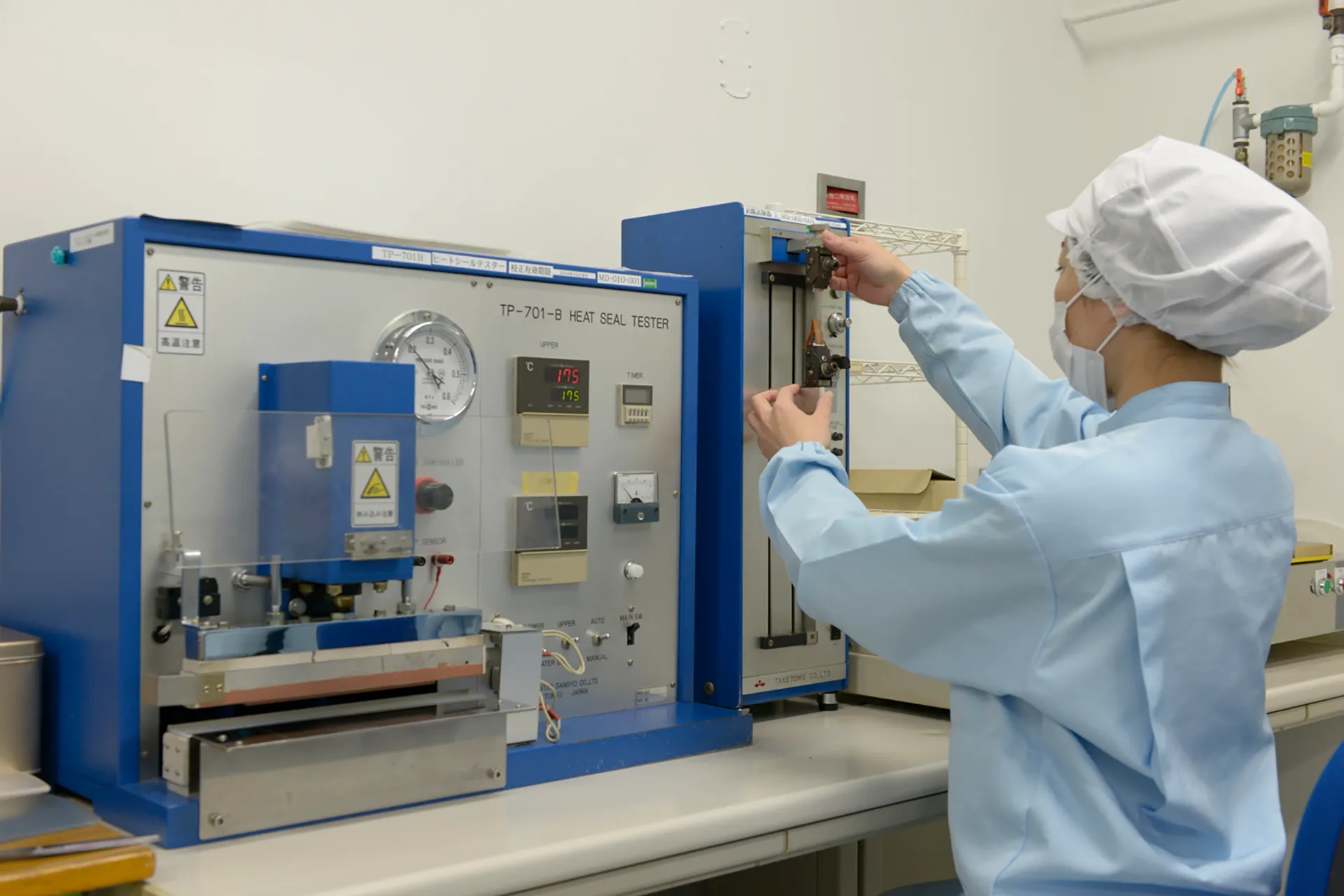

Schopper Tensile Strength Tester

Taketomo’s main target industries include pharmaceuticals, food, and electronic devices—fields that demand delicate quality and absolute safety. To meet these stringent requirements, we implement comprehensive quality control measures based on GMP standards and conduct thorough product inspections at every stage of the process.

To prevent contamination from foreign substances or dust, our factory is equipped with advanced protective features such as insect-proof shutters and air showers. By controlling and managing airflow through room pressure adjustments, we establish different cleanliness levels for each production stage, enabling high-standard printing in some of the industry’s most advanced cleanrooms.

For pharmaceutical and food packaging materials, ensuring quality is not achieved by a single final inspection. Instead, we maintain high standards by conducting rigorous inspections at multiple stages of the production process. Our optical defect detection system immediately records and displays any detected anomalies on a monitor, ensuring precise quality control.

Environment

Fundamental Principles

Basic Policy

- 1. Continuous improvement of our environmental management system and pollution prevention

- 2. Development and expansion of environmentally friendly products

- 3. Reduction of environmental impact through operational improvements

- 4. Compliance with applicable legal and regulatory requirements, as well as other agreed-upon obligations

- 5. Promotion of recycling and reuse

- 6. Reduction of waste

- 7. Conservation of resources and energy

- We will set goals based on these principles and work diligently to achieve them.

Company

Profile

-

Company Name

TAKETOMO, INC.

-

Head Office

Taketomo Bldg. 1-33-5 Takadanobaba, Shinjuku-ku, Tokyo, Japan

-

Established

April, 1948

-

Capital

JPY 10,000,000

-

Directors

President : Hiroaki Ito

Senior Managing Director : Koichiro Ito

Managing Director : Yasuyuki Fujikawa

-

Osaka Sales Office

I&F Umeda Bldg. 8F, 3-10-2 Toyosaki, Kita-kum Osaka-shi, Osaka

-

Mida Distribution Center

1780-6 Mida, Kounosu-shi, Saitama

-

Factory

SANKO ALUMI INC.

-

Address

362-24 Akagidai, Konosu, Saitama

-

Established

December, 1970

-

Capital

JPY 100,000,000

-

Directors

President : Hiroaki Ito

Senior Managing Director : Motoyoshi Ito

Director: Yasuyuki Fujikawa

-

Subsidiary

TAKETOMO Vietnam Company Limited

Room 4. 01B, 4 Floor Phuong Tower, 31C Ly Tu Trong St.,

Ben Nghe Ward, District 1, Ho Chi Minh City, Vietnam

-

Business Activities

Manufacturing and sales of packaging materials for Pharmaceuticals, Foods, and other products.

Sales of Aluminium foils and related products

Manufacturing and sales of IC tags

-

Bank Accounts

Mizuho Bankk

MUFG Bank

Sumitomo Mitsui Bank

History

Our History

-

1948.04

Founded at the current headquarters location, began manufacturing and processing packaging materials for pharmaceuticals and food products.

-

1950.05

Established agency partnership with ToCelo Corporation (now RM ToCelo Corporation), expanding market share in processed sales of their products.

-

1969.03

Began agency business with Mitsubishi Reynolds Aluminum Co., Ltd. (now MA Aluminum Co., Ltd.), entering the aluminum foil processing market.

-

1969.09

Started agency business with Mitsubishi Plastics, Inc. (now Mitsubishi Chemical Corporation) and began selling PVC films.

-

1970.05

Constructed new headquarters building.

-

1970.12

Relocated manufacturing operations to Konosu City, Saitama Prefecture, and renamed the company to SANKO ALUMI INC., expanding production capacity for future demand.

-

1976.04

Constructed and commenced operations of a new factory, enhancing awareness of GMP standards for pharmaceutical packaging materials and establishing a thorough inspection system.

-

1988.12

Installed a multi-color gravure printing machine, strengthening the printing division.

-

1990.06

Started selling Water Treatment Equipment.

-

1991.09

Built a distribution warehouse adjacent to the factory.

-

1994.04

Completed construction of a new headquarters building at the current location.

-

1995.11

Installed the six-color gravure printing machine.

-

2001.12

Started selling Morian Heat Pack (heating agent and heating bag).

-

2005.01

Relocated factory to Kawasato Industrial Park, Saitama Prefecture, constructing a clean factory suitable for pharmaceutical and electronic material production and introducing coating machines.

-

2005.05

Installed an eight-color gravure rotary printing machine for film printing.

-

2005.06

Installed a three-color simultaneous dual side printing machine for PTP aluminum foil.

-

2006.09

Installed inline and offline defect detection system.

-

2012.05

Expanded PTP aluminum foil production with the introduction of a dual-side simultaneous printing machine.

-

2013.05

Installed a dual-side simultaneous inspection machine for PTP aluminum foil.

-

2014.04

Established Osaka sales office.

-

2016.05

Increased capacity with an additional dual side simultaneous inspection machine for PTP aluminum foil.

-

2017.03

Opened the Mida Distribution Center.

-

2017.04

Expanded with an additional dual side simultaneous printing machine for PTP aluminum foil.

-

2017.08

Introduced an offline defect detection system for printing.

-

2019.02

Added a high-performance large-scale slitter machine.

-

2020.06

Modified the three-color aluminum foil printing machine for lamination processing and launched the lamination business.

-

2021.05

Opened Vietnam office.

Access

Address

- Taketomo Bldg. 1-33-5 Takadanobaba, Shinjuku-ku, Tokyo, Japan

- Phone: +81-3-3209-7231

- Fax: +81-3-3209-4551

- Email: info@taketomo.co.jp

- 1-minute walk from Toyama exit of Takadanobaba sta., JR Yamanote Line

- 1-minute walk from Toyama exit of Takadanobaba sta., Seibu Shinjuku Line

- 4-minute walk from Exit 3 of Takadanobaba sta., Tokyo Metro Tozai Line