Products

Aluminium Foil for PTP

TAKETOMO's Superior-Precision and Superior-Quality Aluminium Foils for Pharmaceutical Packagings

Manufactured under strict quality managements, our products complies with Japanese standards such as notifications from the Ministry of Health, Labour and Welfare. It is also registered in the FDA (U.S. Food and Drug Administration) Drug Master File and with the NMPA (National Medical Products Administration).

Dual-Side Printing Alignment

IR contamination inspection system

Barcode Printing

Data Matrix

Data Matrix

QR code

QR code

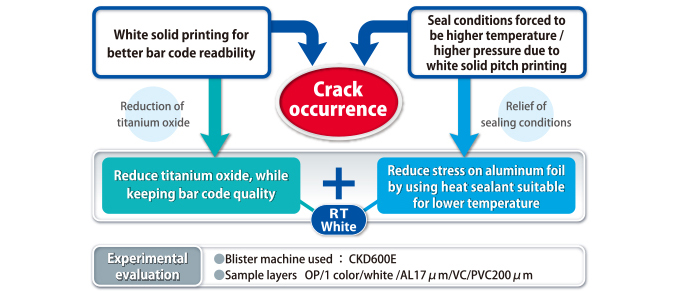

RT White™ - Titanium oxide reduced PTP Aluminium foil

Patent No. 5681247

Available options

- Dual-Side Printing Alignment

- Barcode / 2D Code printing

- IR inspection compatible printing

- Other custom specifications

- Please contact us for any other requirements.

Container Film for PTP

Manufactured under GMP control.

Conformance to various standards

PVC sheets produced using precision calendering equipment and sheeting technology, as well as CPP sheets manufactured through multi-layer extrusion and advanced formulation techniques, comply with domestic and international standards such as the MHLW notifications, FDA regulations, and PL standards.

Moisture-proof PVC sheet for tablet and capsule packaging "VINYFOIL™ for PTP"

- ■Rigid PVC sheet: Vinyfoil C-series

- This rigid PVC sheet is manufactured using precise calendar facilities and sheeting technologies. Various grades are available to satisfy quality requirement regarding moistureproof properties, light shielding properties, and moldability.

- ■Moisture-resistant PVC/PVDC multilayer sheet: Vinyfoil F-series

- This moisture-resistant sheet is mainly composed of rigid PVC and vinylidene chloride (PVDC) This material exhibits significantly better moisture-resistance performance than rigid PVC alone. Different grades are available with improved pocket extrudability, impact resistance, and light shielding properties over conventional products.

- ■Moisture-resistant PVC/PCTFE sheet: Vinyfoil L series

- This moisture-resistant sheet is composed of rigid PVC and polychlorotrifluoroethylene (PCTFE). Various grades are available in accordance with your requirements.

Moisture-proof CPP sheet for tablet and capsule packaging "SUPERFOIL™ for PTP"

- ■CPP sheet: Superfoil E-series

- This CPP sheets has various grades: Light-shading, damp-proof, moisture-proof, etc.

- ■Bioplastic sheet: Superfoil B-series

- This product is manufactured using plant-based materials and contributes to reducing greenhouse gas emissions.

Laminated film (for pharmaceutical product and food packaging)

Pharmaceutical and Food Packaging Films to meet diverse requirements

laminated film Laminated film for stick bag Biomass ink printing

Expertly crafted packaging design

The experience accumulated over the years has given us an abundant knowledge of package design that enables us to handle a wide variety of laminated products for pharmaceutical and food manufacturers.

We propose products that utilize special types of film to meet diverse needs. In addition to fulfilling basic functions such as storage and protection of contents, these films can offer more advanced functions such as tear resistance and chemical resistance.

Lineup

- Pillow bags for pharmaceuticals

- Gazette bags for PTP sheets, flat bags, etc.

- Pharmaceutical primary packaging

- Stick bags, 3-side seal bags, 4-side seal bags, etc.

- Food packaging

- Zipper bags, stick bags, 3-side seal bags, 4-side seal bags, cup lid materials, etc.We can supply in your requested form like films, welded plastic bags, containers, molded items, and others.

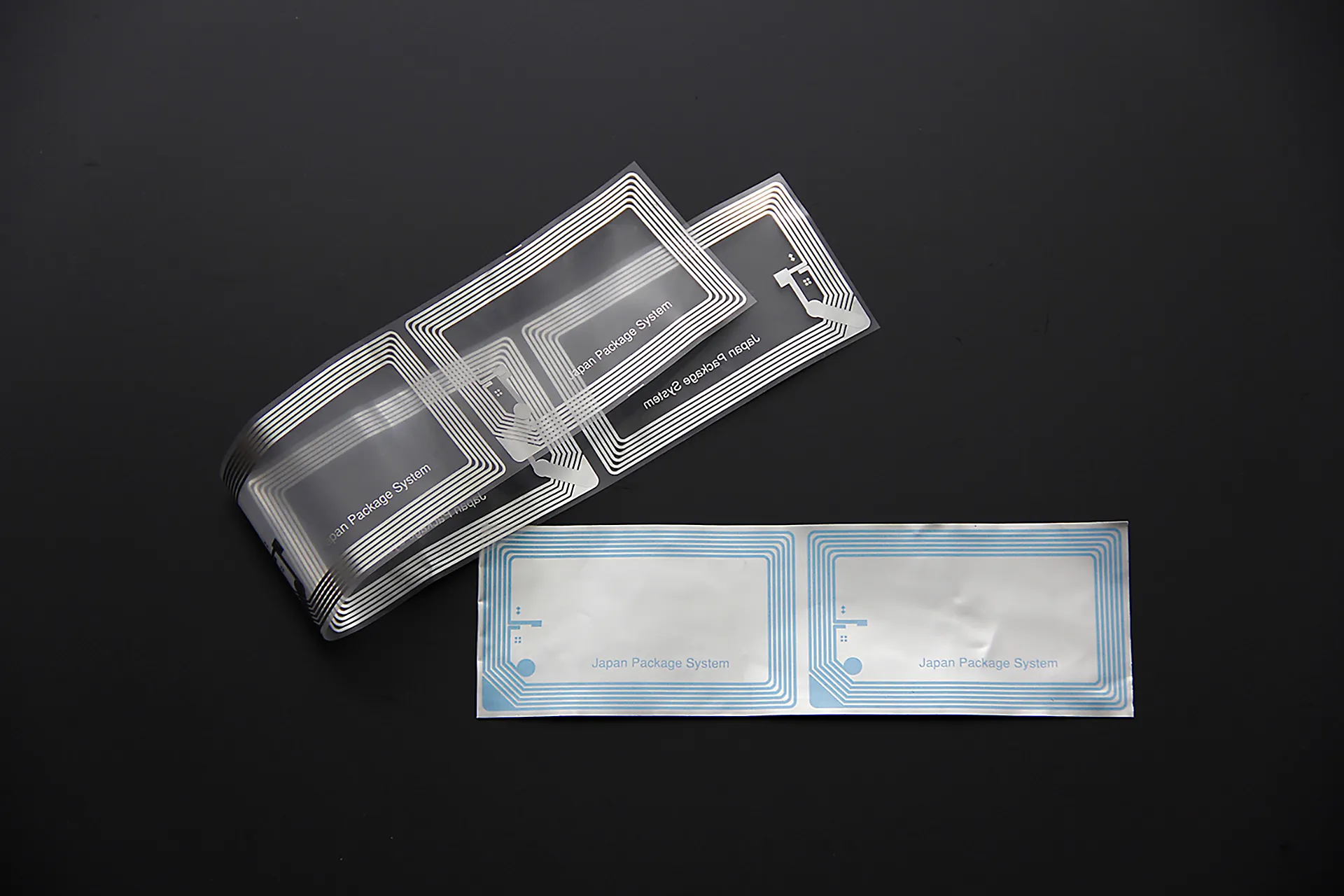

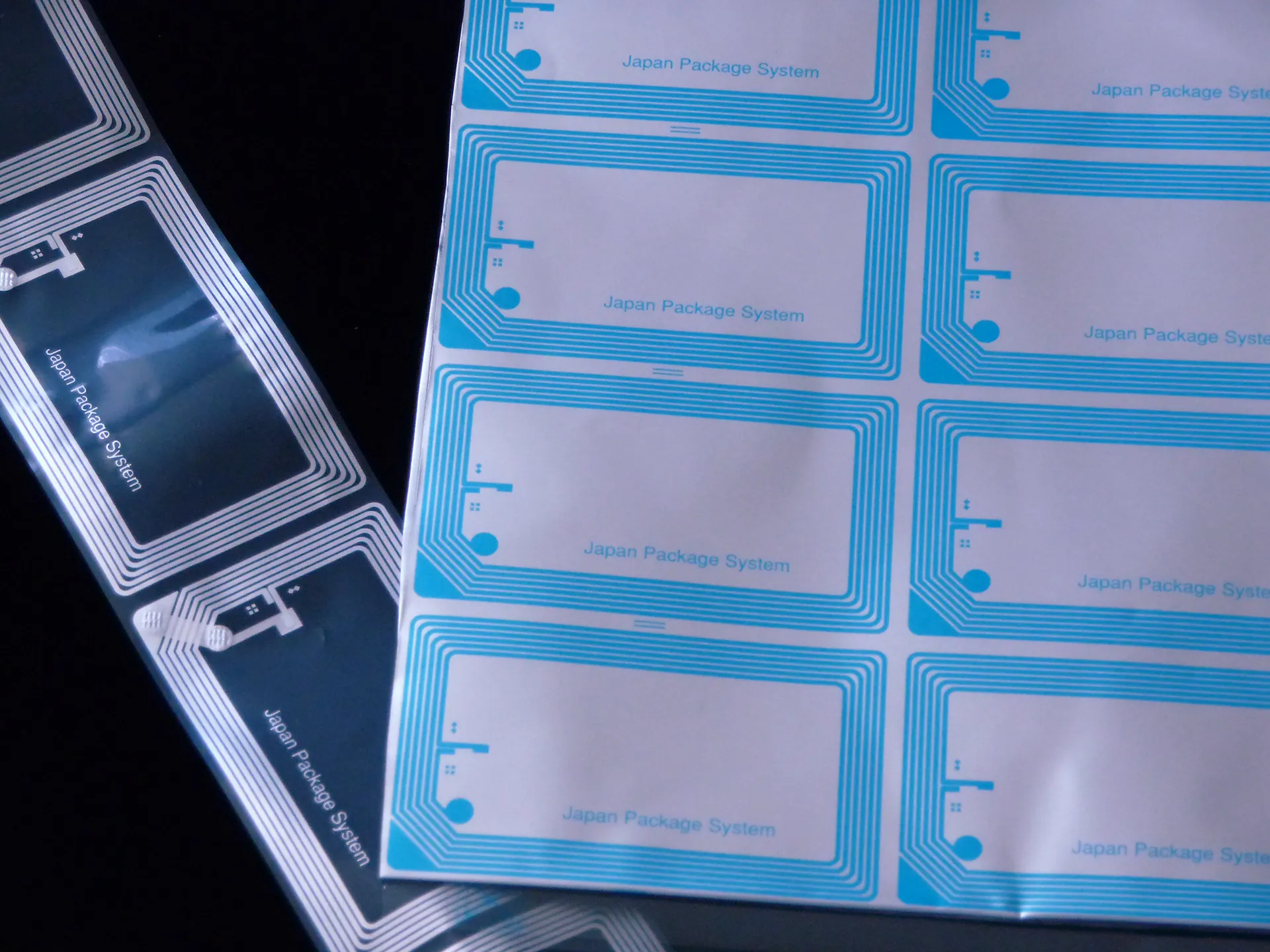

IC tag antenna manufacturing

Highest Quality IC tag products manufactured by the best printing technology, equipments, and environmental managements